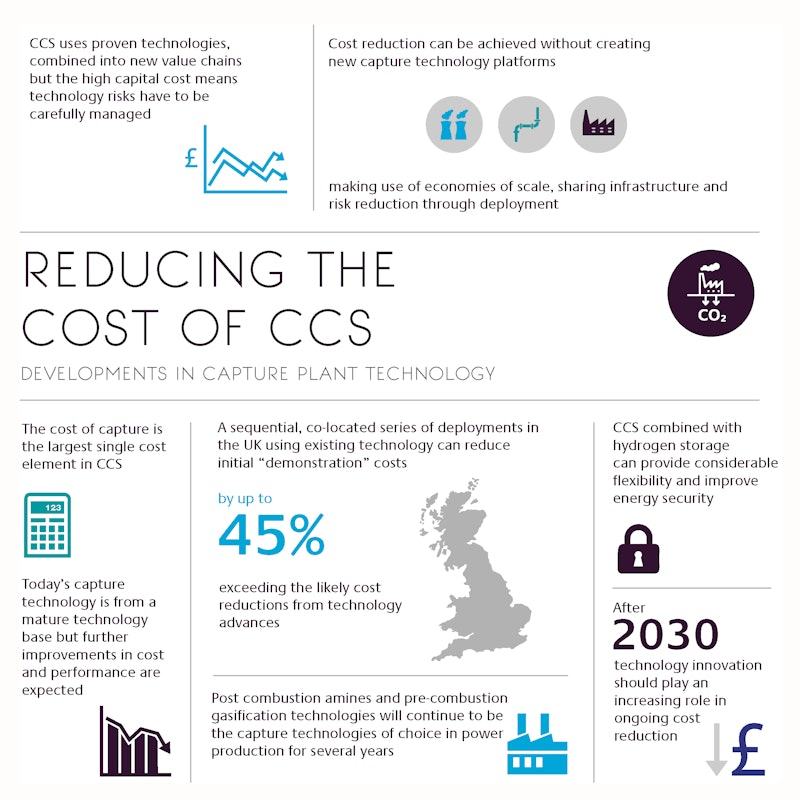

Reducing the cost of CCS - Developments in Capture Plant technology

Dennis Gammer

Strategy Manager

Reducing the cost of carbon capture and storage

CO2 has been extracted from hydrogen plants and natural gas plants for use in EOR since 1972. Conventional amine technology has been used to separate CO2 from natural gas at the Sleipner gas field in Norway since 1996 where it is stored purely for environmental reasons (CCS). Further natural gas amine applications were developed at In Salah in Algeria and at Snohvit in Norway in 2004 and 2008 respectively. More recently, Sask Power has been running Shell’s Cansolv process at a coal plant at full scale for over a year and so this option has been uniquely derisked for coal power stations, and a real First of a Kind (FOAK cost base established from which reductions could be made.

Cancellation of the DECC CCS Commercialisation Competition in the UK and consequently the Peterhead project will delay the demonstration of the Cansolv process on a gas (CCGT) power plant. Pre-combustion technology should be operational at Kemper County power station in 2016. CCS plants for hydrogen production (Canada, USA) have been operating since 2013 and several industrial CCS plants are in construction. By 2017 22 plants in eight countries will be running full chain CCS technology spanning post combustion and precombustion coal, natural gas steam reforming, bioenergy CCS (corn to ethanol) and applications in the power, gas production, refining, chemicals and steel sectors according to the Global CCS Institute Project Database. Capturing CO2 from a power station incurs additional capital cost, similar to the cost of the original power station and in itself uses up to 20% of the power station output.

Dennis Gammer

Strategy Manager

Dennis Gammer joined the ETI as Strategy Manager, Carbon Capture and Storage in 2010. He has 30 years’ experience in technology development and licensing and is a chartered chemical engineer